Industrial

Industrial plants and facilities have unique needs. Our expert craftspersons are up to the task, with decades of experience under their belts

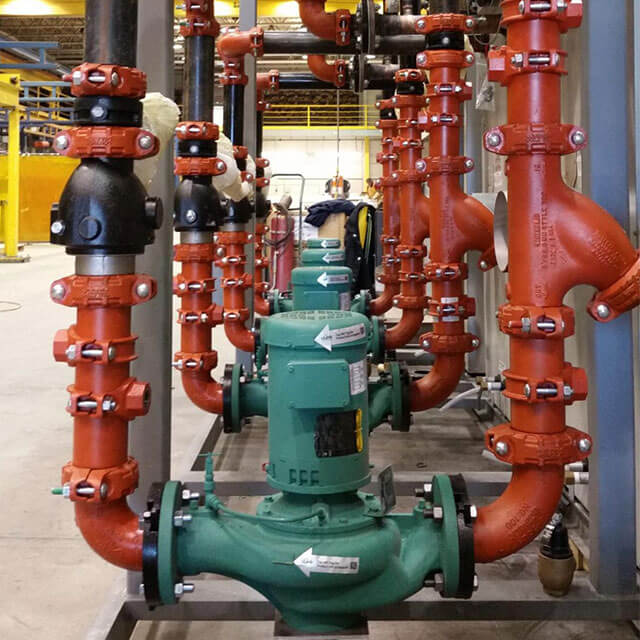

Industrial Mechanical Services

Yearout’s team does it all: design, fabrication, installation, and maintenance for industrial buildings of any size or complexity. When it comes time to upgrade your HVAC, plumbing, or piping systems, our service technicians are dedicated to doing the work with as little disruption to your business as possible. With our creative solutions, we are often able to minimize shutdowns.

New Construction

Yearout’s Capital Projects team has decades of proven experience managing new construction industrial building projects. Each industrial client has unique requirements for their new building. Our design-build and design-assist services are the best in the industry. Our team uses the latest technology to meet not just your requirements – but your vision. Yearout’s fabrication team can design and build the systems you need to make your industrial building’s HVAC, plumbing, piping systems, and boiler systems work seamlessly with all the other new systems. We provide commissioning services to ensure that the systems we build work as designed.

Get a Quote Today

What We Do

- HVAC Service

- Industrial Mechanical Maintenance

- Plumbing Services

- Design/Build and Design/Assist

- Energy Services

- Fabrication

- Boilers & Service

Here When You Need Us

Yearout is a trusted name in industrial mechanical construction and maintenance. Companies in the industrial space know they can depend on our service technicians to be there when you need them. Not tomorrow – or next week – but today. At any hour – day or night.

Our Promise

We are industrial maintenance specialists committed to providing the highest level of service to our customers. This ethos sits at the heart of our culture and has done so since the day we founded in 1963. Our customer service is unrivaled, and we deliver quality, robust solutions to every client, every time.